How to Choose a Hydraulic Breaker: A Detailed Guide

The hydraulic breaker plays an essential role in modern construction and demolition projects. Choosing the right equipment directly impacts productivity and project success. Selecting the proper hydraulic breaker requires careful consideration of several key factors. This guide helps users understand how to choose hydraulic breaker correctly for various applications.

What Is a Hydraulic Breaker?A hydraulic breaker is a powerful percussion hammer mounted on an excavator. Operators use it to break hard surfaces like rock, concrete, and asphalt. The breaker uses hydraulic pressure to deliver strong impact energy. This energy crushes and fractures materials efficiently.

Why Choosing the Right Hydraulic Breaker MattersChoosing the proper hydraulic breaker ensures safe and efficient operation. A poorly matched breaker can damage the carrier machine and reduce productivity. Correct selection also extends equipment life and improves job quality. Proper hydraulic breaker selection protects your investment and reduces unnecessary costs.

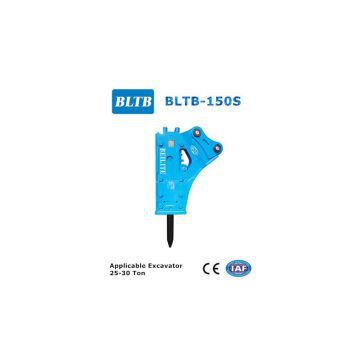

Key Factors for Selecting a Hydraulic BreakerCarrier Machine Weight and SpecificationsThe carrier machine’s weight directly influences hydraulic breaker selection. Operators must select a breaker that matches the carrier’s operating weight and hydraulic capacity. A breaker that is too heavy can overload the machine. A breaker that is too light may not deliver sufficient impact force. Matching the breaker to the machine ensures stable and effective operation.

Working Conditions and Job Site RequirementsDifferent projects demand different breaker specifications. For hard rock applications, users need a breaker with high impact energy. For light concrete demolition, a smaller breaker provides adequate performance. Evaluating the specific working environment helps users choose hydraulic breaker models that suit the task.

Tool Size and Impact EnergyThe breaker’s tool diameter and impact energy determine its breaking capacity. Larger tools deliver stronger impact forces but may slow down in lighter jobs. Smaller tools work faster for minor demolition tasks. Matching tool size to the material ensures efficient performance and prevents energy waste.

Hydraulic Flow and Pressure CompatibilityOperators must confirm that the hydraulic breaker matches the carrier’s hydraulic system. Proper hydraulic flow and pressure ensure the breaker operates effectively. Mismatched flow rates can cause power loss and equipment failure. Verifying hydraulic specifications guarantees stable performance and long-term reliability.

Equipment CompatibilityNot all hydraulic breakers fit all excavators. Users must check pin sizes, bracket dimensions, and mounting systems. Selecting compatible equipment ensures simple installation and safe operation. Proper compatibility prevents unexpected downtime and protects both the breaker and the carrier.

Brand Support and After-Sales ServiceReliable after-sales support ensures quick access to spare parts and technical assistance. Choosing brands like Hydraulic Breakers from Beilite guarantees consistent product quality and service. Access to local service centers can significantly reduce maintenance time and costs.

How to Select the Proper Hydraulic Breaker SizeCorrect breaker size improves productivity and protects the carrier machine. To select the right size, users must consider the following:

The carrier’s weight and hydraulic flow range

The material hardness and job type

The required breaking force and working speed

Proper sizing prevents damage, ensures fast operation, and maximizes work efficiency. Consulting equipment specifications helps operators select the proper size quickly.

Hydraulic Breaker Selection for Different ApplicationsBreaking Hard RocksOperators breaking hard rocks must select hydraulic breakers with high impact energy and larger tool diameters. These breakers provide the required force to fracture dense materials.

Concrete DemolitionConcrete demolition requires medium-sized breakers with balanced power and speed. These breakers remove reinforced concrete efficiently without overloading the carrier.

Road ExcavationFor road surface breaking, lighter breakers offer sufficient performance. They allow fast movement and quick breaking cycles, improving job efficiency.

Common Mistakes When Buying a Hydraulic BreakerOperators sometimes select a breaker based solely on price, ignoring specifications and compatibility. Others choose equipment without considering hydraulic system requirements. Some ignore maintenance support when making purchasing decisions. Avoiding these mistakes ensures safe operation and reduces unexpected costs.

How to Maintain a Hydraulic Breaker for Long-Term UseProper maintenance significantly extends the breaker’s service life. Operators should follow these practices:

Regularly inspect hydraulic hoses and connections

Check tool bushings and replace them when worn

Lubricate breaker tools frequently

Monitor hydraulic oil quality and replace it on schedule

Avoid dry firing to prevent internal damage

Consistent maintenance keeps the breaker running efficiently and prevents costly downtime.

Beilite Hydraulic Breaker Product AdvantagesBeilite designs hydraulic breakers that deliver stable performance and reliable durability. The products support a wide range of excavator models and offer easy installation. Beilite provides strong after-sales service, ensuring timely parts delivery and professional technical support. Customers benefit from quality products and responsive service teams.

Key TakeawaysSelecting the correct hydraulic breaker requires careful consideration of the carrier machine, job site conditions, tool size, hydraulic compatibility, and equipment support. Matching these factors improves work efficiency, ensures safe operation, and protects the investment. Beilite offers high-quality hydraulic breakers with strong service support to help customers make the best selection.

Contact Us for Professional Hydraulic Breaker SelectionContact Beilite for expert advice on hydraulic breaker selection. Our specialists help you select the proper equipment for your project. Reach out today to get the right solution for your job site.

Frequently Asked QuestionsHow to choose the right hydraulic breaker size?To select the correct size, operators must match the breaker to the carrier’s weight and hydraulic system. They must also consider the material hardness and breaking force required. Consulting the manufacturer’s sizing charts helps select the proper model quickly.

What are the key factors for selecting a hydraulic breaker?Key factors include the carrier’s specifications, job site conditions, required impact energy, hydraulic system compatibility, and equipment mounting dimensions. Operators should verify each factor before purchasing.

Can a hydraulic breaker work with all excavator models?No, hydraulic breakers do not fit all excavators. Operators must verify pin size, bracket dimensions, and hydraulic flow rates to ensure compatibility. Using incompatible equipment may cause safety risks and reduce performance.

How to maintain a hydraulic breaker for long-term use?Regular maintenance keeps the breaker in good condition. Operators must inspect hoses, replace worn parts, lubricate tools, monitor hydraulic oil, and avoid dry firing. Consistent care extends service life and prevents damage.